MudMaster™ 5000 Wash Rack System

Washes, Contains and Recycles Wash Water

Wash Rack Features the RTS Closed-Loop Filtration System

From the sun-baked deserts of the Middle East to the oil and gas fields of the U.S., the Riveer MudMaster™ 5000 wash rack system has met the demanding challenge of washing military vehicles, construction equipment, waste haulers, and other hardworking rigs clean and reclaiming the run-off. Mud, muck, dust, and dirt are no match for MudMaster’s water cannons, solids separation technology, and filtration. Where the payloads are heavy and the roads are long, you’ll find MudMaster right at home.

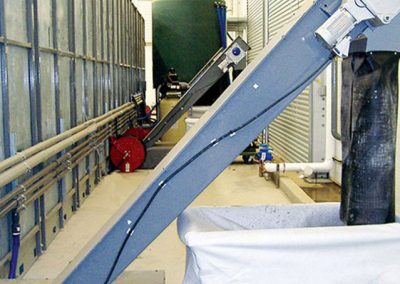

MudMaster 5000 starts with high flow water cannons and is followed by high-pressure. As the water cannon blasts the muck off the vehicle, the solids stream is channeled to Riveer’s patented automatic drag conveyors built into the wash pad. No other company offers this unique system that incorporates wedge wire screen filtration before the wash water enters the filtration system.

The MudMaster 5000 incorporates the Riveer RTS 5000 water treatment system that starts with a 850-gallon settling chamber with built-in mud conveyor to remove settled solids in real-time. This system handles huge amounts of dirt and mud by utilizing a built-in conveyor.

Riveer knows that handling mud is the hardest task for any wash rack and that is why only Riveer wash racks are equipped with automatic conveyors to drag the mud to hoppers, both from the rack and the stainless steel filtration system. Once in the hopper, the mud can be easily disposed of with a forklift. No other company has anything like this. Thanks to robust industrial filtration technology; MudMaster is ready to run for years in the toughest applications.

Every MudMaster features Riveer’s GripStart™ 0n/off system, making it easy for driver or operator to wash his equipment quickly and easily.

Riveer wash lanes are usually 18′ wide with 6′ high overspray walls; however, custom sizes are available. The non-skid flat (not undulating) surface provides the users with a safe and comfortable deck to work on. The low deck height, 6″ is significantly lower than any other wash rack and makes for safe low angle drive on ramps. The wash pads can be any length and can be equipped with automatic mud conveyors to ease cleanup.

Behind-the-Scenes Look at a Closed-Loop Wash Rack System

Watch to see how a MudMaster and RTS 3000 water treatment system are assembled piece by piece in this stop-motion video. The MudMaster handles moderate to heavy mud loads, and consequently is used for equipment washing on job sites and maintenance areas. The MudMaster employs the RTS water treatment system to add the extra automation that higher dirt loads demand.

The ARC’s 175 PSI is safe for aircraft, spraying 10 gallons of water per minute through each wash wand. This spray helps meet strict TM requirements for aircraft rinsing and decontaminating operations. The ARC’s spray is low-pressure enough to not damage aircraft equipment, but high volume enough to effectively rinse common areas of entrapment.

The ARC effectively rinses large areas, greatly reducing rinse time. Dual guns on the ARC allow two users to perform the rinsing, reaching 200 total feet of surface area. When used simultaneously, the dual guns are still able to produce effective flow rates, and can easily spray an additional 40 feet for rinsing tail sections and larger aircraft. Simultaneous use of the dual guns does not negatively impact flow rates. In addition, the spray can easily extend 40′ for rising tail sections and larger aircraft.

While corrosion control is a necessity, it also shouldn’t require all of your time. Riveer’s ARC is easy to operate and maintain. The trailer-mounted, standalone unit is completely self-contained. This also means the ARC is easily transported and towed with HMMV, TUG or other common AGE. The ARC features a 6 to 28 inch tall tow bar, surge brakes, stout and full boxed trailer construction.

It also includes a 7000 axle set rating. Baffles help stabilize the ARC’s tank by minimizing the free-surface affect. Riveer’s ARC is transportable in accordance with MIL-STD-209, 1791, and 913.

It can also operate in a variety of environmental conditions. Optional hot water exponentially improves the effectiveness of the rinse in removing corrosion causing contaminants. You also do not need to spend hours of training. Simple controls and an intuitive layout minimize the need for operational training. The ARC does not require calibration and is ready to work when delivered from the factory.

ARC operates on JP-8 and other common aircraft fuels or diesel. Onboard or external supplies of water can be used to supply the ARC. A 1000-gallon tank (2000-gallon optional) holds fresh water, allowing for a continuous and length run time when no water is nearby.

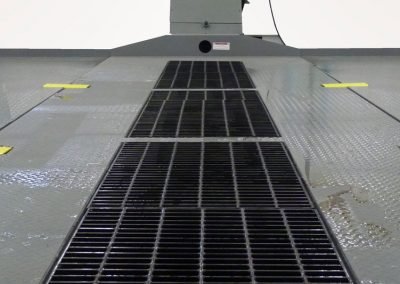

Riveer Patented Wash Rack Dry-Deck

Riveer patented Dry-Deck allows water to flow under the deck to collection trough, keeping work area dry.

- 18′ x 42′ drive-through wash pad

- Non-skid smooth surface, no trip hazards

- Low profile, 6″ deck height

- Low angle, 3 degree ramps at both entrance and exit

- 90 ton capacity, 3 times higher than undulating portable racks

- The dry-deck design keeps rack dry

- Water drains through top surface to channels that carry water to collection troughs

- Automatic mud conveyor dumps mud into the portable hopper

- Wedge wire vacuum filter leaves solids behind (patent pending)

- 2 hot water pressure washers with 75′ of hose on reels mounted flush to sidewalls

- 2 foam guns with 75′ of hose on reels mounted flush

to sidewalls - 2 water cannons with 75′ of hose on reels mounted

flush to sidewalls - All reel cabinets are heated for all-weather operation

- Push button controls in ruggedized NEMA 4 enclosures

- 6′ high galvanized overspray walls along both sides

Wash Rack Filtration

- Housed in ISO container for use in any environment, the MudMaster’s RTS closed loop filtration unit features:

- Zero discharge, environmentally compliant

- Only filtration system with built-in mud conveyor

- Corona discharge ozone

- Continuous recirculation

- Absolute filtration

- Oil skimmer

- GripStart control

- Completely automatic operation

- Oil Coalescing

- 1200-gallons of mud settling

- Automatic oil skimmer

- High-pressure back washable media filter

- Nominal and Absolute filtration

- PLC controlled

- Continuous recirculation

- Continuous ozone injection

- MudMaster meets all US and CE electric standards; UL, TUV, IEC, NEC, NFPA.