Hangar Aircraft Washing System

Hangar Aircraft Washing System

Hangar Aircraft Wash and Rinse System, Zero Emission, Plug and Play

Hangar aircraft washing is finally here.

Conducting wash operations in the refuge of a hangar offers protection from water evaporation, and premature soap dehydration caused by wind and varying temperature. While most hangars are equipped with drains for washing indoors, very few are equipped with a wash system that complies with TM 1-1500-344-23-2, TO 1-1-691, NAVAIR 01-1A-509-1 guidelines for aircraft safe washing.

Technical manuals are very specific relative to the damage caused by washing with a standard, high pressure system that can drive water into mechanical struts, avionics panels and air frame seams resulting in long-term, irreversible damage. The aircraft-safe water pressure Wingman provides the optimal solution.

Historically, modifying a hangar to implement or replace wash systems can involve many different authorities, delaying readiness beyond acceptability.

While many shortcuts involve towing diesel powered wash systems into the hangar for intermittent use, safety and health concerns limit this as a long term solution. The growing concern regarding enclosed space operation of diesel fired units combined with the need for readiness NOW has driven the development of the Wingman, a total electric system enabling plug and play capability utilizing MIL Spec connections for water and electricity commonly found in hangars for use with existing ground support equipment.

Some of the features of the Wingman:

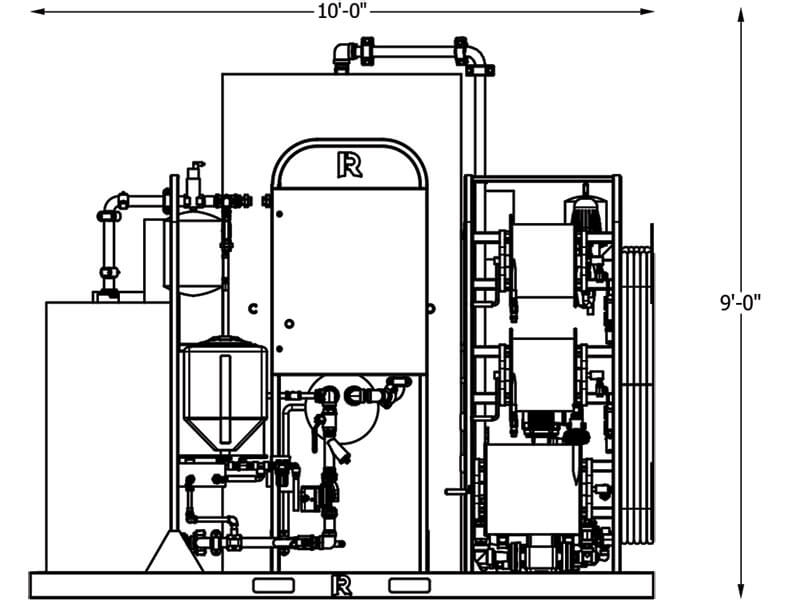

- 2 Rinse Guns- 10 GPM flow rate each with variable spray

pattern control - 1 Foamer gun- 50 GPM

- Configurable operating pressure to meet airframe specific guidelines

- 30-80 PSI (Boeing) configuration, or 175 PSI

- 500 gallons of hot water @ 140˚F

- Variable frequency drive pumps (VFD) with stainless steel pump heads

More Wingman Features:

- Powder coated skid

- Insulated hot water tank

- Water connection: ¾” garden hose fitting and 2″ NST hydrant connection

- Electric connection: X1806-71 Crouse Hinds plug

- Powder coated hose reels

- Run dry protection

- Total electric, zero emission

- Ultra-high efficiency boiler section exceeds DoD building standards for 95% efficiency

- No exhaust stack required, no venting required.

- Reach up to 50’ from ground, less need for lifts or ladders

Built to Standards:

NEC 2017/NFPA30: National Electric Code as adopted in 2017

MIL-STD-461: Requirements for the Control of Electromagnetic Interference Characteristics of Subsystems and Equipment

MIL-STD-209K: Interface Standard for Lifting and Tie down Provisions

MIL-STD-810G: Environmental Engineering Considerations and Laboratory Tests

UL 508A: Standard for Industrial Control Panels

NFPA 70: National Electric Code

Wingman Specifications:

Part Number: HWHW-10F

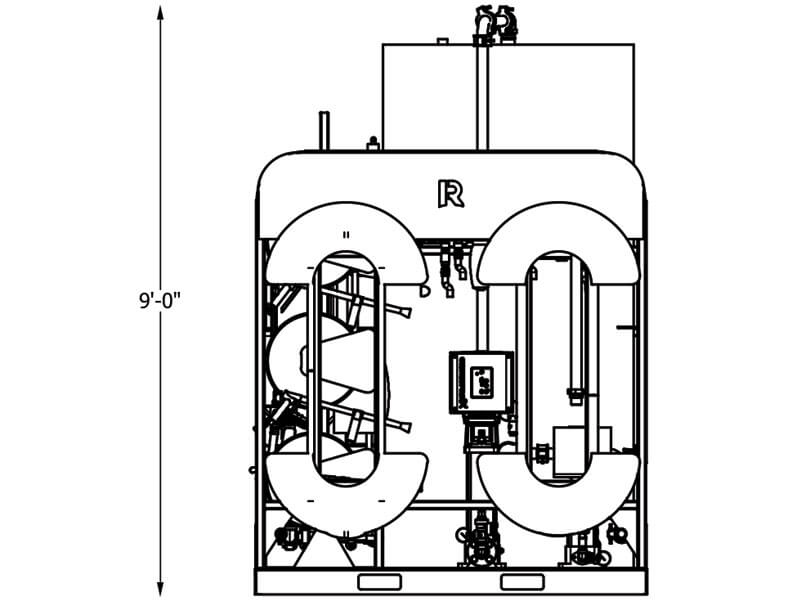

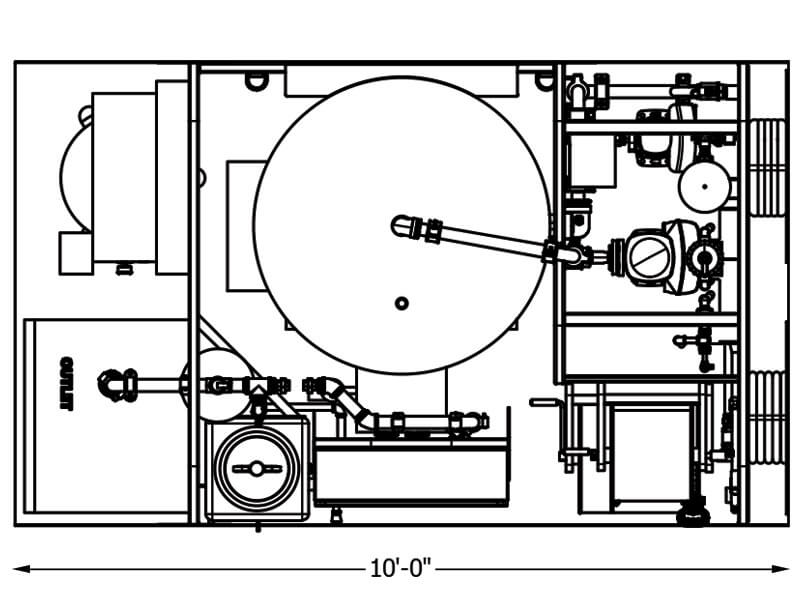

Length: 10’ 0”

Width: 6’ 0”

Height: 9’ 0”

Dry weight: 2,900lbs

Cage: 5X781