TAWS: Total Aircraft Washing System

The best aircraft wash equipment. Safer pressure. Hot water. Rinse and wash.

TAWS: Total Aircraft Washing System

The best aircraft wash equipment. Safer pressure. Hot water. Rinse and wash.

Total Aircraft Washing.

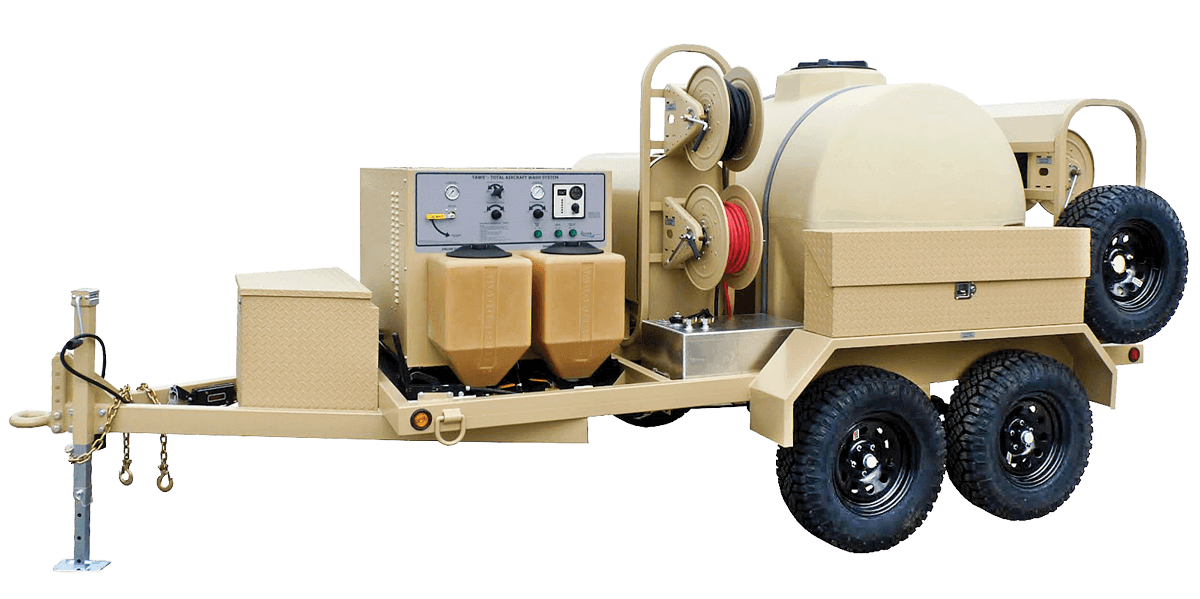

The Riveer Total Aircraft Washing System (TAWS) is the total package, producing high-flow rates that greatly reduce cleaning time while still effectively washing large surfaces.

With a built-in air powered high-pressure foamer, the TAWS can cover the side of a CH47 (750 sq. ft) in less than 60 seconds. The TAWS’s efficiency is further supplemented by dual guns for two users and 200′ of total reach. And even while used simultaneously, will still produce high flow rates.

TAWS Features Include:

- US Navy and US Army approved for fixed and rotary wing.

- 140°F hot water wash and rinse.

- Proprietary turbine engine flush.

- High-pressure foamer.

- Safe-for-aircraft 175 PSI.

- Completely self-contained.

- Built-in high flow air powered foamer.

- Ideal for anti-corrosion PM of civil and military aircraft.

- Easily transported with highway approved lights and brakes.

- Dual wands for faster rinsing.

The system is low-pressure enough to be safe for the aircraft, but high-pressure enough to reach exposed steel, hinges, actuators, gear bays and other corrosion-prone areas.

Quick connect yoke gives the user 10 GPM to reach 30’ high surfaces, such as tail sections.

The spray can also easily reach 30 additional feet for cleaning large aircraft and tail sections. To lessen the possibility of mess, all hoses are on reels, and all guns have storage brackets and fit inside toolboxes for easy storage.

Each gun sprays 5 gallons of 140-degree water per minute, operating at a safe 175 PSI. These specifications meet the strict TM requirements for aircraft wash, rinse and decontamination procedures.

TAWS Additional Features:

- 10-gallon soap concentrate capacity.

- 10-gallon gas path solution tank.

- Run dry protection.

- Full enclosure for engine and pumps.

- NEMA 4 electrical construction.

- AGSE parking brake and DOT trailer.

- Unique hinged engine cover with 360-degree access to all service components.

- Kubota® water-cooled diesel engine coupled with Cat® pressure pump.

- Easily drained for storage and transport with large dump valves.

- Dexter® axles with load sharing spring perches keep consistent tongue weight.

- 1600# tongue jack with fast pin.

- HD structure with custom frame to provide a low center of gravity.

- Perimeter protection bumper to prevent damage to frame.

- Fenders are tough stand on bumpers for access to the top of the water tank.

- Advanced AGM battery for long storage life and exceptional power.

- LED light package conforms with DOT requirements, recessed within frame for protection.

TAWS Meets Strict Guidelines

Riveer TAWS was designed in conjunction with the U.S. Army for the purpose of aircraft cleaning in deployed locations. Top concerns were the harsh desert environment and the need for reliable systems in remote operations. This superior design, including water delivery system rated to perform aircraft washes and meet the washing and pressure guidelines in TM 1-1500-344-23-2. The TAWS trailer has won Riveer competitive contracts for washing system equipment from multiple branches of the US Military as well as numerous foreign military sales.

TAWS is Easily Transportable

Another benefit of the TAWS is its ability to be easily transported. It can be towed with HMMV, TUG, or other common AGE. It has a 6 to 28-inch tall tow bar and features stout and fully boxed trailer construction with a 7000# axle set rating. The TAWS also includes recessed 12v/24V LED lighting and both 7 pin RV and NATO style trailer wiring connectors are provided. Kevlar® Reinforced Goodyear® tires are resistant to tears and punctures round out the list of high-quality transportation features that come together to make moving the TAWS a simple process.

Simple and Fast Fast Aircraft Wash

Not only is the TAWS easy to operate and maintain, but its trailer-mounted unit is completely self-contained. The TAWS is also able to operate in a variety of environmental conditions from 34 degrees F to 140 degrees F. Minimal operator training is required. With an intuitive layout and onboard operational instructions, TAWS operates on JP-8 and other common aircraft fuels or diesel. On-board or external supplies of water can be used to supply TAWS. A 525-gallon tank holds fresh water, allowing for extended run times between fill ups.

Turbine Engine Flush

The turbine engine flush is a vital and important part of the TAWS allowing for mandatory turbine flush procedures when deployed without the benefit of depot level resources. Turbine cleaning requires low-pressure and low-flow pumping, both of which the TAWS features. Onboard fluid and compressed air hoses along with a variety of provided turbine flush fittings make turbine flush activities efficient and effective. TAWS effectively cleans aircraft engines by delivering gas path cleaner from an on-board tank. Both gas path cleaner and rinse water are delivered from operator managed controls on the TAWS. A maximum flow rate of 5gpm and a turbine safe maximum pressure of 45psi ensures a proper cleaning cycle without damage to expensive components.