Wash Water Containment in Wash Racks, Wash Booths, and Wash Pads

Above Ground Wash Racks, Wash Booths and Wash Pads

Wash Racks, Wash Pads, and Wash Booths for Equipment Washing and Wash Water Containment

Our goal is always to provide the best solution for your needs. Whether you are looking for a permanent wash facility, a steel wash rack system, or a way to retrofit an existing system in order to improve its efficiency and/or EPA compliance, you can rely on Riveer will design a wash water containment system that best fulfills your unique specifications.

Wash water containment is the first step toward compliance. We can design a containment pad that is either above-ground and made of steel or built-in and poured with concrete. Both options provide seamless integration with our washing and recycling systems, or with your pre-existing provisions.

If you’re looking for a quick turnaround, you can install a Riveer Rack in a matter of hours without having to apply for permits. These bolt-together steel racks are sized to your exact requirements and allow for expansion if needed in the future. If permitting is not an obstacle and portability is not a requirement, an in-ground concrete wash pad can often be a more economical way to go.

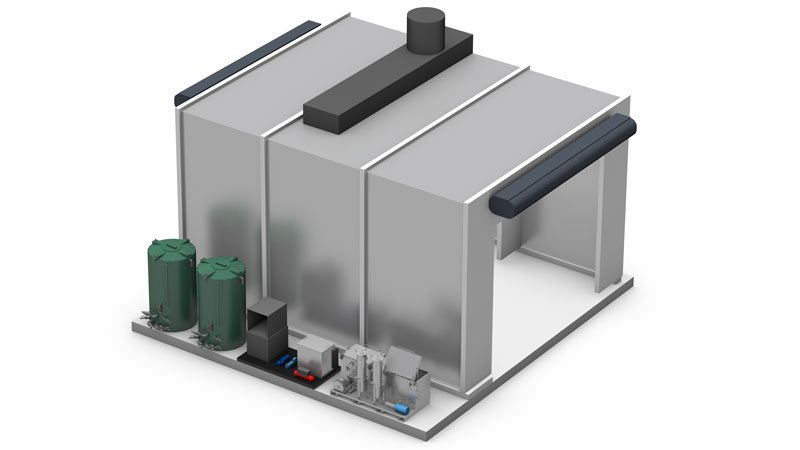

If you are also in need of shelter, lighting, air handling, or mist containment, we can build a wash booth, hanger or facility for your wash operations.

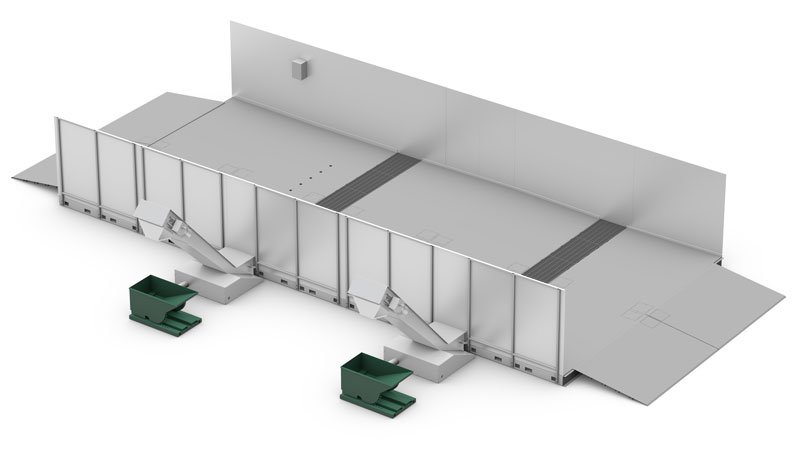

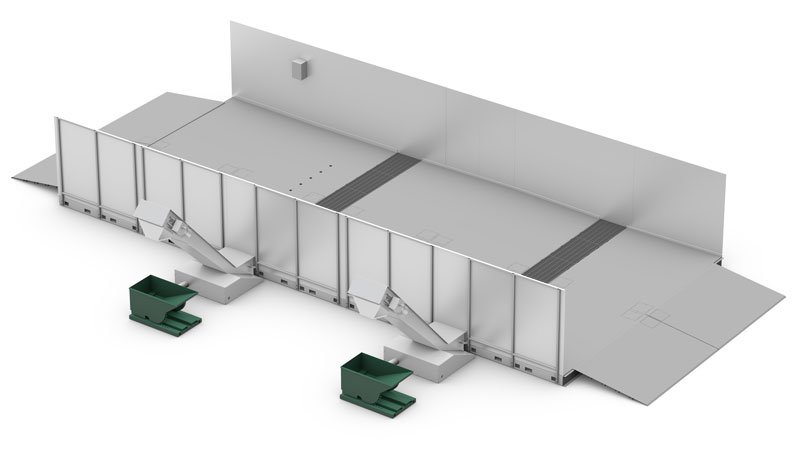

Above Ground Wash Racks

Riveer Above Ground Steel Wash Racks are manufactured in any increment and are designed to carry loads up to 12,000 lbs. per wheel. Because Riveer uses vacuum technology to recover the wash water, these racks are by far the lowest profile racks available. (We have seen racks measuring 21″ high.) Our low profile racks make it easy to even get low clearance man-lifts and forklifts onto the racks for washing. In addition to being easier to get onto, our racks are safer for your equipment and employees. The solid diamond-tread plate decks are coated with grit-impregnated epoxy paint to give sure grip even when wet and soapy.

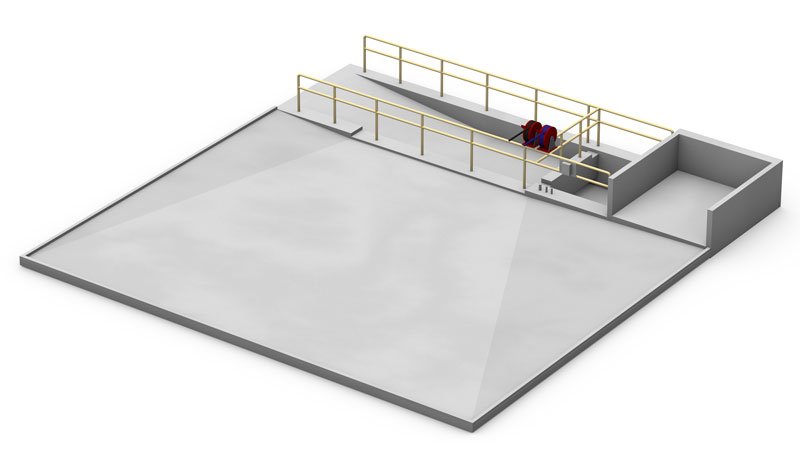

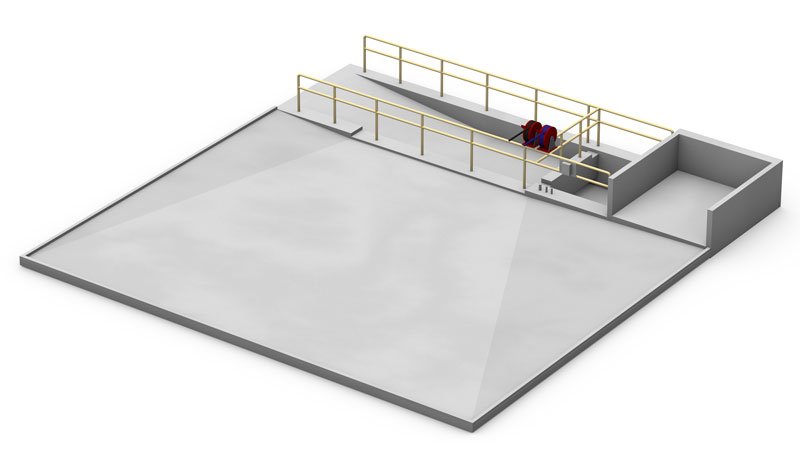

In-Ground Wash Pad

Worksites required to wash a high volume of heavy-duty equipment or rinsing storage and fertilizer tanks may elect to install concrete containment pads. Solids and effluent are typically washed into a sump, where it is pumped into a filtration unit for solids separation or less favorably discharged into the sewer.

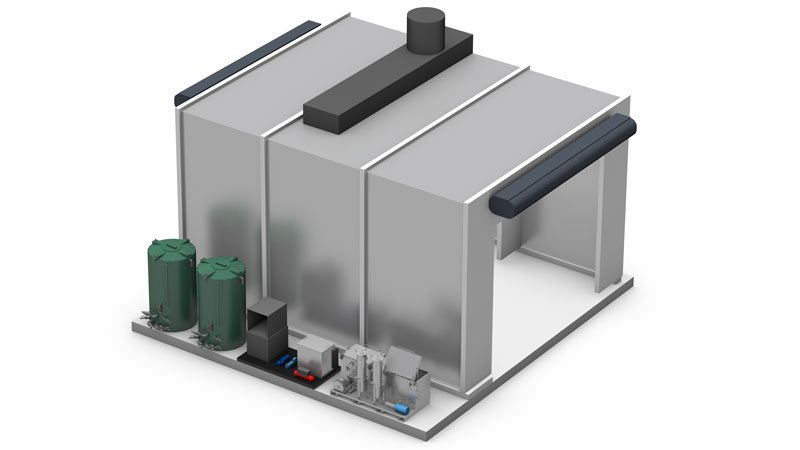

Enclosed Wash Booths

If you need a wash booth in your manufacturing facility that is EPA compliant and helps to lower your operating costs, look to Riveer Engineered Wash Water Recovery Systems. Riveer is your one-stop shop for booth enclosures, pressure washers, and wash water recycling systems; our commitment to providing easy-to-operate systems insures that all of these pieces interface through a single, simply designed control panel to meet your specific operational requirements.