Equipment Washing Booths

Equipment Washing Booths

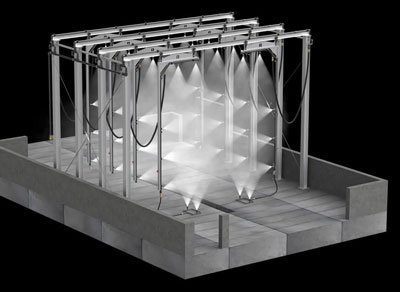

Wash Booths with Water Filtration Systems

Wash Booths + Riveer Systems = Higher Productivity with Lower Operating Costs

If you need a wash booth in your manufacturing facility that is EPA compliant and helps to lower your operating costs, look to Riveer Engineered Wash Water Recovery Systems. Riveer is your one-stop shop for booth enclosures, pressure washers, and wash water recycling systems; our commitment to providing easy-to-operate systems insures that all of these pieces interface through a single, simply designed control panel to meet your specific operational requirements.

The great thing about enclosures is that they create a completely new environment within your current workspace, thereby adding new capabilities to your operation. Fully customized to your specification, Riveer’s endless options will give you optimal functionality and allow you to work within your budget. Degreasing, pretreatment, spot-free rinse, recovery and recycling of wash water or phosphate… you name the operation and we’ll integrated it with your enclosure to provide an easy-to-use turnkey system.

Whether you’re just looking for a straightforward single stage wash or a complex seven stage wash, Riveer is committed to helping your operations run more efficiently and effectively.

Wash Booth Features:

- Precision designed for mist elimination through airflow and water management

- In-ground or above ground configurations available

- Custom sizes and styles available

- Function add-ons including overhead cranes and hose reels

- Integrated recycling and discharge solutions

- High powered hot and cold pressure washer options

- Waterproof lighting provides a bright washing environment

- Climate control options include manual or automatic heat and humidity settings

- Integrated material handling options available to cover many configurations

- Manual wand operations or fully automated wash cycles based on your throughput needs

- Meets all US and CE electric standards: UL, TUV, IEC, NEC, NFPA

Wash Booth Automation

There is really no limit to what Riveer Engineers can come up with. For example, this customer wanted an automated spray system to make his batch operations more efficient. The videos above show a variety of automatic spray systems. The customer’s phosphate booth has a suspended track running through it upon which parts are moved through our phosphate booth, and then on to be powder coated. Instead of someone wearing their arms out wielding spray guns all day, they simply bring in parts, turn the system on and watch it go!

Read about common wash booth applications:

Metal & Surface Pretreatment

Pretreatment systems are complex and nuanced. Riveer has built expertise to provide you with the best products.

Rain Testing

Test your products to make sure they are water-tight with an automated rain testing station.

Automated Washing Systems

Automated pretreatment systems offer repeatable, predictable multi-stage performance.