TACTICAL RINSE SYSTEM (TRS)

An above-grade rinse system with built-in undercarriage spray, water containment pad, and water recycling.

Taxiway Rinse System for Rotary and Fixed Wing Aircraft

An above-grade rinse system with built-in undercarriage spray, water containment pad, and water recycling.

Fully rinse aircraft in minutes with the Tactical Rinse System (TRS).

Riveer’s Tactical Rinse System (TRS) is a deployable clear water rinse system for aircraft of virtually every configuration and complexity.

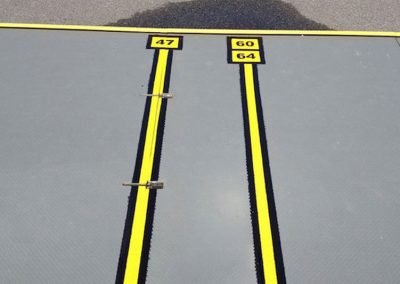

Preventing corrosion buildup is critical to aircrew safety, especially when based near an ocean. The TRS is fully deployable and installed above ground on an existing taxi-way. This saves operators time and money normally used on infrastructure modification and associated site engineering/environmental considerations.

Install the above-ground TRS in just a couple days without having to get Milcon involved and start rinsing aircraft after each flight in a matter of minutes. The modular steel rinse pad contains rinse water and contaminants without requiring any modification to your existing taxiway for environmental compliance.

While you’re protecting the aircraft by rinsing after every flight, the TRS captures and recycles up to 80% of the water for safe reuse within the system, making your operation ultra sustainable. The complete rinse/wash and filtration system is housed within ISO containers. All you need is electrical power.

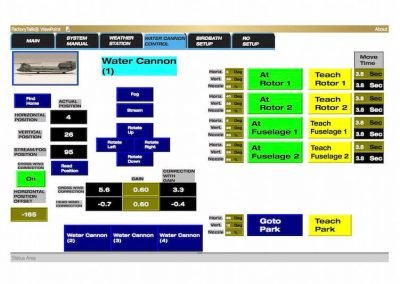

Pilot activated rinsing requires no ground support crew.

The TRS features pilot activation and allows for easy, inline taxi-through aircraft rinsing. Rinse cycle times can be adjusted, depending on size and amount of dust, sand and salt, to accommodate water spray lasting from 30 seconds to 2 minutes. This creates a customized rinse to meet your specific environmental and mission conditions.

Active wind correction keeps rinse sprayers on target.

We use built-in weather monitoring combined with robotic spray nozzle adjustment to make sure the spray always covers the entire airframe, regardless of the weather conditions. We can preprogram specific spray patterns for every style of aircraft you have on-base, so any pilot can rinse anytime they land just by pushing a button inside the plane.

Water supply pretreatment keeps you compliant, and most importantly, safe.

Clean water must be used for aircraft rinsing in order to prevent corrosion and mechanical failures.

The TRS draws water from your on-base supply and runs it through a pretreatment process in compliance with the following MIL standards:

- TM 1-1500-344-23-2

- TO 1-1-691

- NAVAIR 01-1A-509